Copper plate PC board scrap equipment

Use of raw materials:

After the raw materials of the circuit board are customized, metal powder and tree fat powder and fiber powder are separated. More than 98% of the metal powder is copper, and the market price is very high. Generally speaking, the resin powder can be used in the wood molding industry, plywood, plywood or filler. Fiber materials are used more for insulation materials. Their market prospects are very broad, comprehensive utilization of waste, benefit the country and the people.

Process advantages:

1. Good comprehensive performance, effective for PC board, copper-clad plate and scrap recycling. The recycling of various circuit boards containing capacitors is also compatible.

2, this supply line is the upgrade of type A products, on the basis of type A reduced power consumption, no noise, less labor automation procedures, high efficiency, while occupying a smaller area, is the waste (line) road board recycling to the present ideal supply line.

3, the whole set of equipment uses a new dust collector, three-in-one dust removal (cyclone dust removal + electrostatic dust removal + static dust removal) on the air, no exhaust emissions.

4, the appearance of the equipment is clean, no dust bag, replacing the traditional dust collector dust, odor can not solve the problem.

Equipment features:

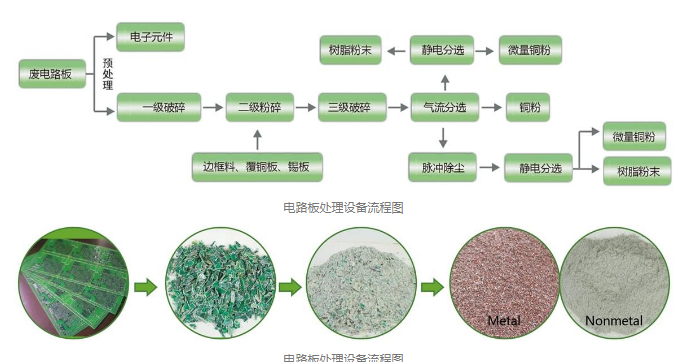

1. The circuit board crusher is used for mechanical crushing and high voltage electrostatic separation. After disassembly, crushing and dissociation, the separation of metal and non-metal is carried out with high purity.

2. The key technology is to organically combine the special crushing and separating equipment of various waste circuit boards to achieve greater energy saving effect in the supply process and achieve a high metal separation rate.

3. The unit energy consumption per ton of waste circuit board processed by circuit board recycling equipment is only about 3/5 of similar domestic products; A single unit can handle up to 1 ton per hour.

4. The price of circuit board recycling equipment is only 1/5-1/3 of similar equipment at home and abroad, and the recovery rate of copper is 3%-5% higher than that of similar supply companies.

5. Good comprehensive performance, it has effect on computer board, computer board, TV board and other line control board. The recycling of various circuit boards containing capacitors is also compatible.

6. Circuit board recycling equipment is the upgrade of wind selection products, less power consumption than wind selection, and no noise, less labor and high automation procedures, improve efficiency, while occupying a smaller area, is the ideal supply line for waste circuit board recycling.

7. Less labor, no noise, and flexible placement of circuit board recycling equipment.

Equipment advantages:

1. The company supply direct supply, according to the customer's different circuit board, copper clad plate materials and processing capacity, can be adjusted configuration;

2. The overall design of the equipment is compact, covers a small area, and saves the site cost of industrial and mining enterprises;

3. Circuit board recycling and processing equipment control * using PLC (digital fully automated control system), uniform feeding during operation, one worker can complete the operation and processing, saving labor costs;

4. The overall performance of the equipment is stable and the noise is low. The magnetic separation function can be selected to separate the iron directly.

5. The complete set of supply line of circuit board recycling equipment is set up a bridge and guardrail, and maintenance personnel can carry out real-time overhaul monitoring and maintenance of the equipment;

6. The equipment adopts new dry physical separation technology, environmental protection, in line with national environmental protection requirements;

7. Air flow plus electrostatic separation process, separation purity up to 99%;

8. The circuit board grinder is equipped with a pulse dust removal system, fully enclosed operation, no dust leakage, in line with the national "comprehensive emission standards for atmospheric pollutants".

Technical parameter:

| Model number | Handling capacity | Power | Apparent dimension | Weight | Recovery |

| DY-400 | 100-200kg/h | 45kw | 4000*3500*4200mm | 4250kg | 99% |

| DY-500 | 200-300kg/h | 68kw | 7000*4000*4500mm | 6500kg | |

| DY-600 | 300-500kg/h | 110kw | 7500*4500*4800mm | 8500kg | |

| DY-800 | 500-800kg/h | 155Kw | 8500*5500*5000mm | 10500kg | |

| DY-1000 | 800-1000kg/h | 198kw | 10000*6000*5250mm | 12500kg |

Maoxin Machinery What are the advantages of cooperation? The key word "win-win culture" recycling wires and cables Copper plate PC board scrap equipment service provider - Maoxin Machinery advocates "win-win cooperation", which means to achieve win-win both internally and externally. Internally, it is Maoxin Machinery employees themselves. The company creates a good atmosphere, ambitious goals, creates a comfortable Maoxin Machinery cultural environment, employees achieve their own career goals and growth, and Maoxin Machinery achieves their interests goals, which is a virtuous circle of "win-win cooperation". Externally, Maoxin Machinery has created good recycling wires and cables Copper plate PC board scrap equipment products and services, and customers have been recognized, providing recycling wires and cables customers with a good service experience, which is also "win-win", and the sense of trust has been further strengthened. This is Maoxin Machinery complementary ecological win-win.