Echelon utilization of lithium battery modules

Energy-saving and emission-reduction benefits people's livelihood, which requires concerted efforts! Maoxin has been committed to technology research and development and product building in the Lithium battery circuit board crushing and recycling equipment field since its establishment, and has accumulated to provide high cost performance [Echelon utilization of lithium battery modules] products for many customers!

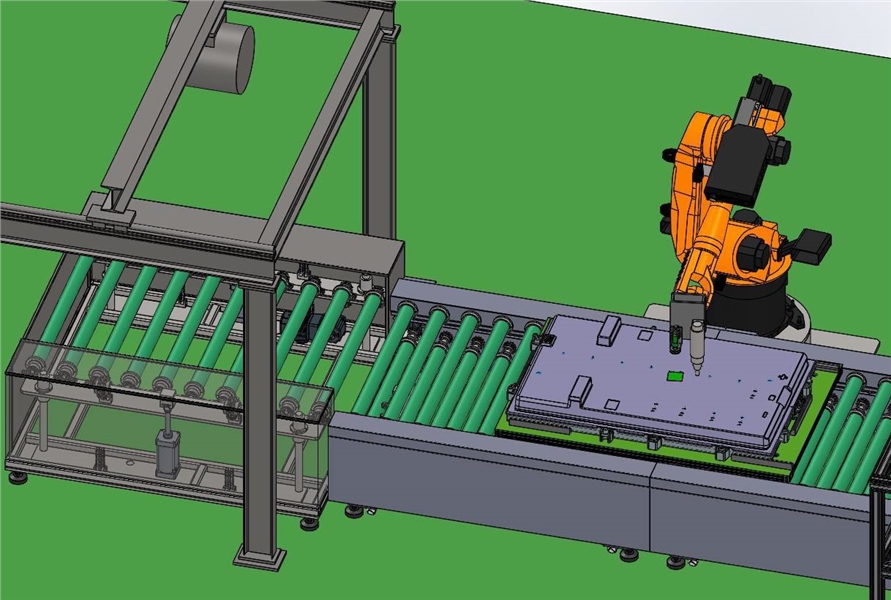

Automatic disassembly introduction:

Automated disassembly consists of two parts. The module is cut and disassembled by manipulator. Automatic cutting and disassembly through image and coordinate positioning to confirm the position.

Module disassembly process introduction:

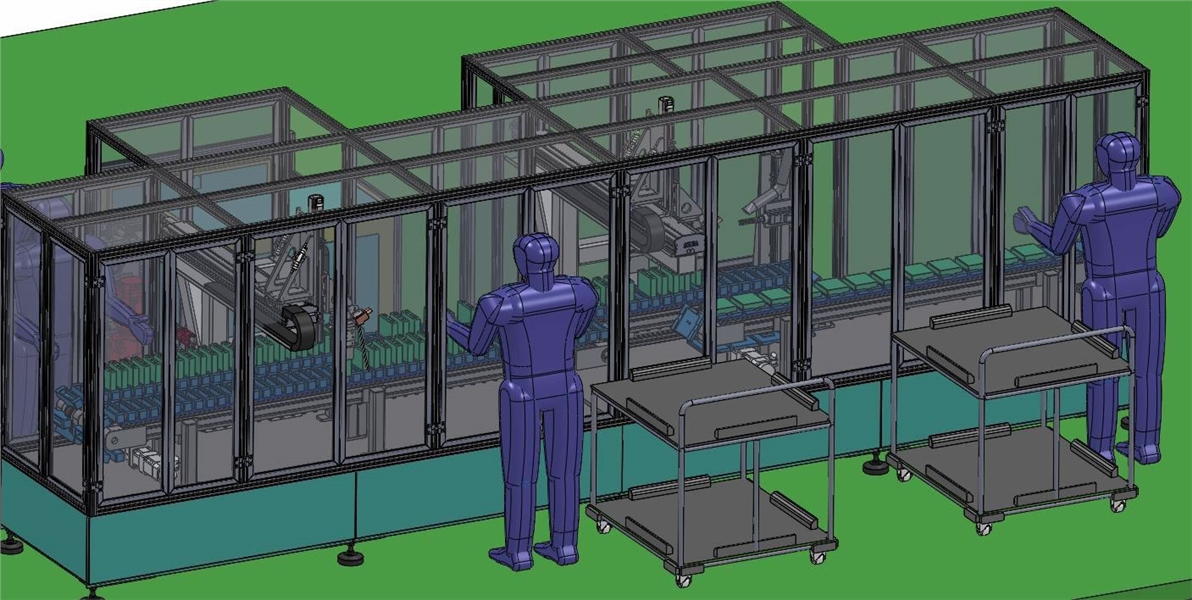

The process is mainly aimed at the disassembly process layout of the power battery module, and the layout is used for the cascade utilization of the power battery.

This process takes a power lithium battery module as the design blueprint, and finally disassembled into:

Single module - Test, direct cascade utilization

Single battery - test, direct cascade utilization

End-of-life batteries - broken recycling

The process layout adopts modular assembly line layout, and the mode of semi-automatic and manual cooperation is adopted to complete the entire dismantling action.

Module process flow:

Module disassembly process:

1. Hoisting: The module to be disassembled is hoisted onto the double speed chain line of the module disassembled;

2. Cut FPC: cut FPC manually;

3. Cache: cache station;

4. Break the rivets: drill the rivets of the module through the electric drill to loosen the fixed rivets of the side plate of the module (the station is equipped with jacking rotation, and after rotating in place, the module can be drilled through the module clamping mechanism);

5. Disassemble the side panels and end panels: manually disassemble the side panels of the module and place the end panels respectively in the designated positions;

6. Disassemble the battery cell: manually remove the surface pad attached to the battery cell;

7. Cut the connecting piece: the artificial auxiliary cutting mechanism will cut the connecting piece on the module;

8. Remove the battery cell: Manually transfer the single battery cell to the module sorting conveyor line.

Maoxin is a Echelon utilization of lithium battery modules product manufacturing enterprise. Since its establishment, it has been deeply engaged in the Lithium battery circuit board crushing and recycling equipment field and has tried to provide technical improvement Echelon utilization of lithium battery modules products for Lithium battery circuit board crushing and recycling equipment customers! Good Chinese products help globalization!